When Labels Are Not Enough: Safety Markings in Industrial Environments

When are labels not enough? Learn how advanced marking systems can enhance safety in industrial environments.

Jun. 11, 2025

Floor labels aren’t always enough. Discover when traditional safety marking fails — and how companies improve safety with LED guidance systems and industrial safety barriers.

Safety marking in industrial settings is essential for preventing accidents and guiding workers through complex environments. The most common forms are safety labels and floor markings, but in many cases, these simply aren’t sufficient.

In this article, we’ll show you when labels fall short and how a well-chosen combination of solutions can significantly improve industrial safety.

When Safety Labels Are Not Enough

1. Wet or cold floors

In environments with moisture, condensation, or low temperatures, adhesive performance drops drastically. Labels start peeling off within days, leaving areas poorly marked—or not marked at all.

2. Mechanical wear and tear

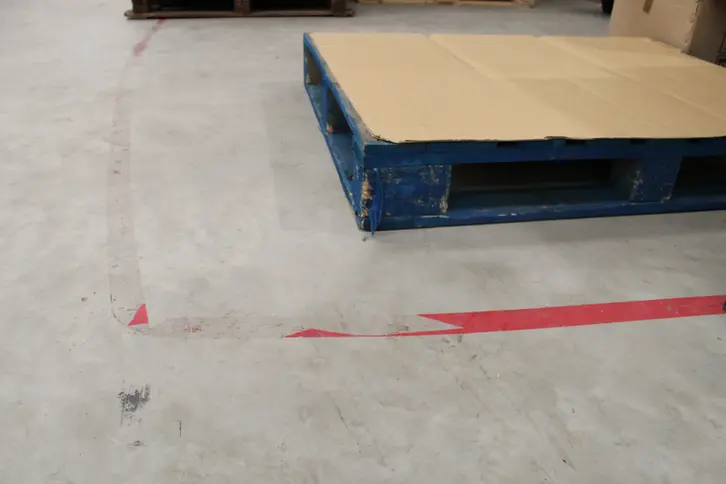

Forklifts, pallet trucks, and industrial cleaning machines cause heavy abrasion. Standard PVC floor labels are not designed for these conditions and quickly fade, crack, or detach.

3. Dust, dirt, and oil

On floors contaminated with oil, grime, or dust, labels struggle to adhere. Even when applied, they are quickly covered by dirt, reducing their visibility.

4. Poor visibility

In dimly lit areas, standard floor markings simply aren’t visible enough. Visual light-based safety solutions become essential here.

How to Choose the Right Type of Safety Marking for Your Facility

Every industrial environment is different, and so are the safety solutions it needs. Before upgrading your marking system, consider the following questions:

• What are the conditions of your floors? (Dry, wet, oily, dusty)

• Are there heavy mechanical loads? (Forklifts, tuggers, carts)

• Are there areas with limited visibility or lighting?

• Do visitors or new employees need to find their way easily?

• Is physical separation between people, machines, and vehicles required?

If you answered yes to any of the above, then standard labels are likely not enough.

Common Mistakes in Safety Marking

Even with the best intentions, safety marking can fail if it's not adapted to real-world conditions. Here are some of the most common mistakes we see in industrial workplaces:

1. Wrong material choice

Standard PVC labels are often used in environments with moisture, oil, or heavy wear, where they quickly peel off or vanish altogether.

2. Poor surface preparation

Labels applied to unclean, wet, or oily surfaces lose adhesion within days. No material can perform well without proper preparation.

3. Lack of physical barriers

Relying only on visual signals in dynamic environments with heavy machinery is risky. Industrial safety barriers are often a necessary layer of protection.

4. No light-based warnings

In low-light or noisy spaces, visual light alerts (such as LED lines or projection symbols) solve problems that traditional signs cannot.

5. Misalignment with workflow

We often see markings that obstruct natural movement or don’t match the actual workflow. Ineffective placement can create confusion or even new hazards.

What Are Better Alternatives to Standard Labels?

✅ Light-Based Safety Marking

In dusty or low-visibility environments, traditional warnings often fail.

👉 Discover solutions with LED lines, projected symbols, vehicle-mounted safety lights, and visual alerts that perform where other methods can’t.

✅ Industrial Safety Barriers

Protect employees and equipment from forklift collisions and moving machinery.

👉 Learn how A-SAFE industrial barriers enhance safety and reduce damage costs in real-world factory environments.

If you're relying solely on adhesive labels, there’s a strong chance you're not providing adequate protection in all conditions. By combining durable floor markings, LED safety systems, and physical barriers, you can significantly reduce injury risks and build a stronger safety culture in your company.

CONTACT

|

Jurij Žvab Cable Management | Industrial Identification | Safety at Work T: +386 40 755 559 |